Capabilities

Centers of Excellence to Power Your Program.

RTCA’s capabilities span a full spectrum of advanced aerospace manufacturing. With expertise in 5-axis machining, lights-out production, assembly and test, landing gear, and structural components, our facilities deliver precision and scale under one trusted brand. Whether it’s complex machining or fully integrated assemblies, our centers of excellence ensure the quality and performance you demand — on time, every time.

Lean Flow Cells & High-Volume Production

RTCA’s Lean Flow Cell Center of Excellence supports high-volume, high-mix manufacturing across aerospace, defense, space, semiconductor, and military/munitions sectors. Our single-piece flow cells deliver dozens to hundreds of parts daily with repeatable precision.Utilizing SMED, Kanban, and lean principles, each flow cell is tailored for efficient machining, assembly, test, and kitting. These value-added, process-controlled environments reduce inventory, shorten lead times, and maximize customer flexibility.

Lights-Out Manufacturing

RTCA’s Lights-Out Manufacturing Center of Excellence enables 24/7 autonomous production through 4-axis and 5-axis machining cells deployed at one or more of our facilities. Supporting aerospace, military, space, medical, and semiconductor components, these cells maximize spindle uptime and operational efficiency.Featuring multi-pallet systems with up to 32 positions and robotic arms on linear rails, these lean, automated environments deliver cost-effective, high-mix/high-volume production with consistent quality and fast turnaround.

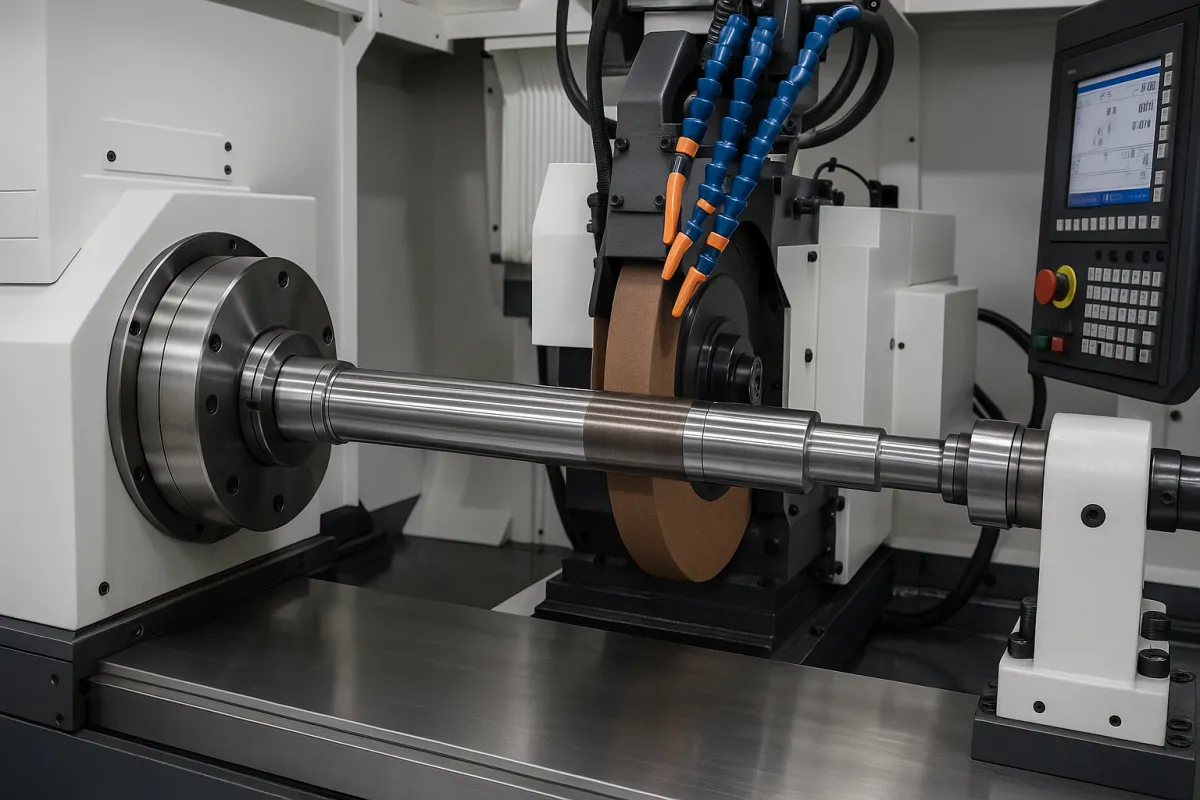

Precision Grinding & Surface Finish Systems

RTCA’s Precision Grinding & Surface Finish Center of Excellence delivers tight-tolerance, high-performance grinding for landing gear components, cylinders, actuation sub-components and related assemblies. Utilizing various machining, processing and grinding technology including CNC Studer OD/ID grinders, we routinely hold sub-micron tolerances and high precision surface finishes as low as 2 µin Ra or better on HVOF-coated, chrome-plated, and heat-treated surfaces.Our expertise spans commercial and military aerospace, industrial hydraulics, and heavy equipment sectors — all supported by robust process control and in-cell inspection.

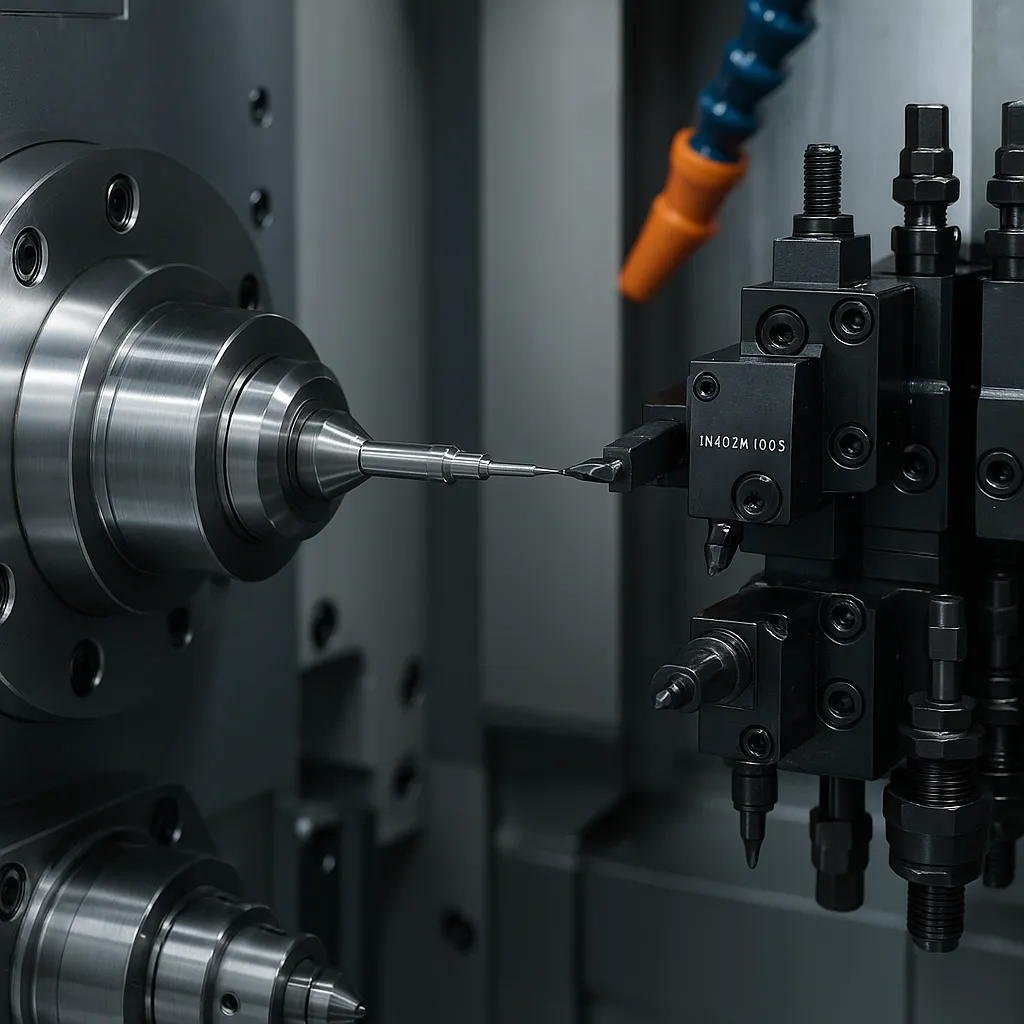

Swiss Machining

RTCA’s Swiss Machining Center of Excellence is dedicated to the high-precision production of small, complex components with tight tolerances and excellent surface finishes. With a fleet of advanced Swiss-type CNC lathes — including up to 7-axis machines — we support high-mix, high-volume manufacturing across aerospace, defense, medical, and other demanding industries.Swiss machining is ideal for producing long, slender, or intricate parts in a single setup, reducing secondary operations and improving efficiency. Our enterprise-wide capabilities enable lights-out production, consistent quality, and lean throughput — delivering reliable parts with lower total cost and faster lead times.

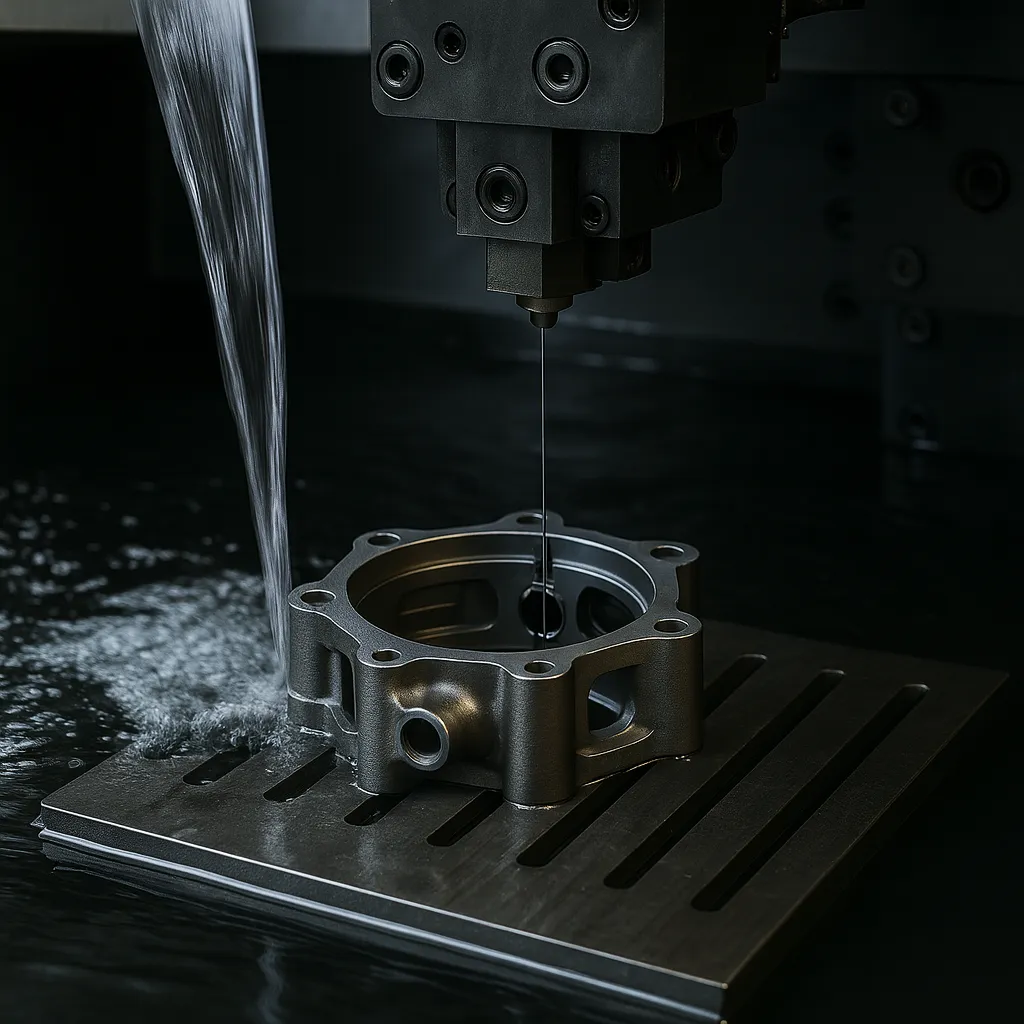

Electrical Discharge Machining (EDM)

RTCA’s EDM Center of Excellence delivers unmatched precision for complex parts that traditional machining methods can’t reach with exceptional accuracy and consistency.

With a range of advanced EDM equipment across our enterprise — including both wire and sinker EDM systems which enables sub-micron accuracy, no tool deflection, and burr-free features — making it essential for producing gyroscopes, missile components, aerospace hardware, and high-precision medical devices. Our process expertise allows us produce mission-critical aerospace and space components in hardened steels, titanium, Inconel, and other exotic alloys.

@ Copyright 2025 - RTC Aerospace | All rights reserved

Design by Media Gurus AI